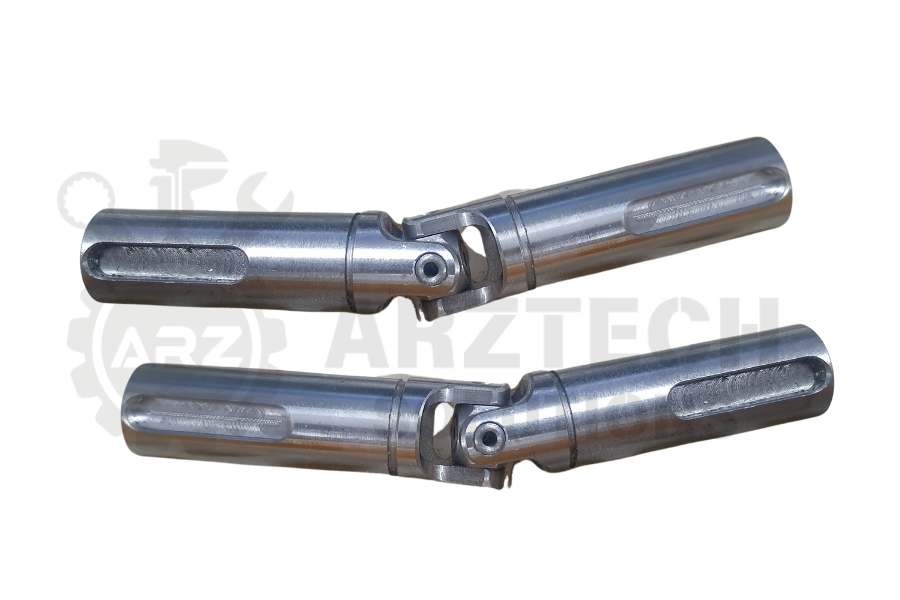

Our high-quality Universal Joints ensure smooth power transmission, durability, and reliability for various industrial and automotive applications.

Key Features

- Allows torque transmission between two misaligned shafts—accommodates angular, radial, and axial movement.

- Engineered to handle heavy loads and high-speed rotations without performance loss.

- Made from forged steel, alloy steel, or stainless steel for excellent strength and wear resistance.

- Available with keyed bores, splined shafts, hex bores, and custom fittings.

- Manufactured to meet international quality and dimensional standards.

What is a Universal Joint?

A Universal Joint (U-Joint) is a mechanical component that allows the transmission of rotary motion between two shafts that are not in a straight line, or in other words, between two misaligned shafts. The U-Joint typically consists of a cross-shaped component, with four arms connected by needle bearings, ensuring smooth rotation despite angular misalignment.

These joints are commonly found in many types of machines, including automotive, industrial, and agricultural machinery, where they provide the necessary flexibility for the shafts to transfer motion at various angles.

Uses of Universal Joint

- Automotive Industry: Universal joints are integral to the driveline systems of vehicles, connecting the driveshaft to the wheels and allowing the transmission of power while accommodating the movement of the vehicle's suspension.

- Agricultural Equipment: U-joints are essential in agricultural machinery like tractors and combine harvesters, ensuring that rotational motion is transferred between various parts like the power take-off (PTO) shaft.

- Industrial Machinery: U-joints are used in conveyors, cranes, and other heavy-duty equipment that require a flexible transmission of rotary motion over a range of angles.

- Aerospace: In the aerospace industry, U-joints are used in complex systems like aircraft landing gear and control mechanisms, ensuring the reliable transfer of motion while compensating for misalignments in critical machinery.

- Marine Applications: Universal joints are found in boat and ship engines, helping to connect the drive shaft to the propeller while adjusting for the angle of movement of the boat.

Additional Information

- Design Variations: Universal joints come in various designs, such as single U-joints, double U-joints (also known as double-cardans), and constant velocity (CV) joints, each designed for specific applications with differing performance requirements.

- Materials: U-joints are commonly made from durable materials like high-carbon steel, stainless steel, and alloys that provide strength and resistance to wear. In harsh environments, U-joints may be coated or lubricated to prevent corrosion and extend their lifespan.

- Maintenance: While U-joints are generally robust, they can suffer from wear and tear, especially if lubrication is insufficient. Regular inspection and lubrication are essential for ensuring the longevity of U-joints. In the automotive industry, U-joints may need to be replaced periodically depending on vehicle use.

- Performance Factors: The efficiency and reliability of a U-joint depend on factors such as load capacity, operating angles, speed, and lubrication. It is critical to choose the right U-joint for each application to ensure optimal performance.